The Bill of Materials (BoM) is a crucial element in the manufacturing process, acting as the blueprint for production. It outlines the components, materials, and instructions required to manufacture a product. In Odoo, the BoM module is a powerful tool that helps manufacturers manage their production processes efficiently and accurately. This blog will delve into the details of the Bill of Materials in Odoo, exploring its features, benefits, and how to set it up for your manufacturing operations.

What is a Bill of Materials (BoM)?

A Bill of Materials (BoM) is a detailed list of raw materials, components, assemblies, and sub-assemblies needed to produce a finished product. It also includes information on quantities, sourcing, and assembly instructions. The BoM is essential for planning, inventory management, and ensuring that the manufacturing process runs smoothly.

Key Components of a Bill of Materials

- Product: The final product that is being manufactured.

- Components: The individual parts or raw materials needed to create the final product.

- Quantity: The specific amount of each component required.

- Routing: The sequence of operations or steps needed to assemble the product.

- Work Centers: The specific locations or machines where each operation takes place.

Types of Bill of Materials in Odoo

Odoo offers flexibility with different types of BoMs to cater to various manufacturing needs:

Manufacturing BoM

This is the most common type, used when manufacturing a product from raw materials or components. It specifies the components required, their quantities, and the operations involved in the production process.

Kit BoM

In a Kit BoM, the final product is not assembled but is sold as a kit of separate items. This is commonly used in scenarios where the customer assembles the product themselves.

Subcontracting BoM

Subcontracting BoMs are used when part of the manufacturing process is outsourced to a third party. In this case, the subcontractor uses the provided components to produce a specific part or the entire product.

How to Create a Bill of Materials in Odoo

Creating a BoM in Odoo is a straightforward process. Here’s a step-by-step guide:

Navigate to the Manufacturing Module

- In your Odoo dashboard, go to the Manufacturing module.

Create a New BoM

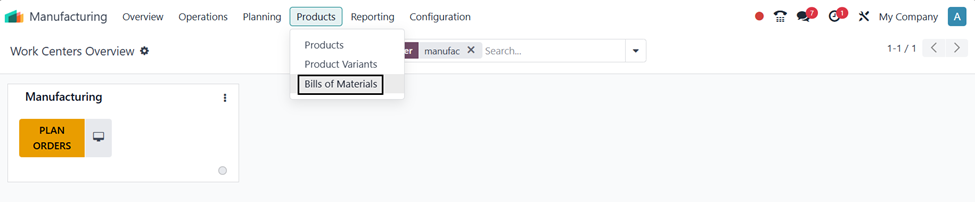

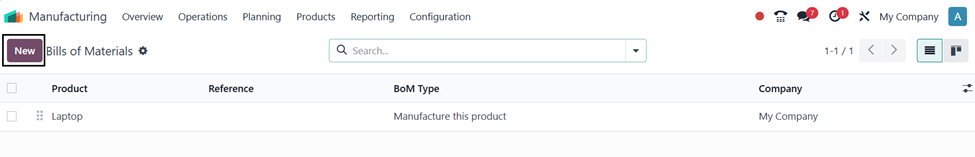

- Click on Products in the top menu and select Bill of Materials.

- Click the New button to start a new BoM.

Define the Product and its relevant information

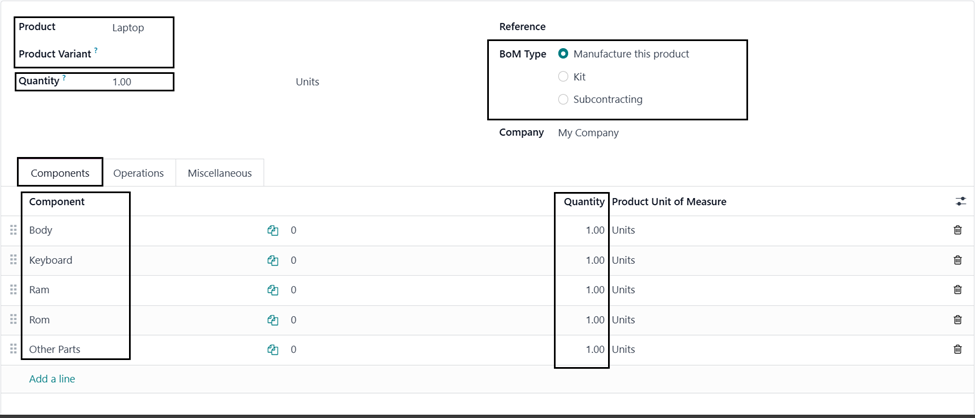

- Select the Product or Product variant for which you are creating the BoM.

- Select BOM Type

- If it’s a new product, you can create it directly from this screen.

- List all the components required to manufacture the final product.

- Specify the quantity of each component needed.

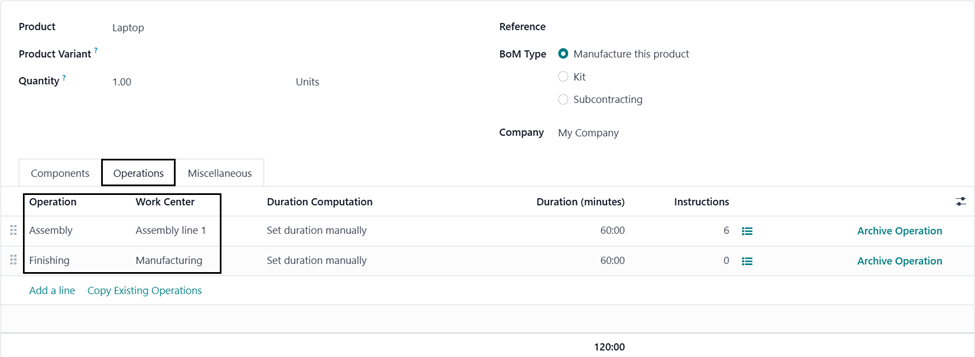

Set Up Routing and Operations

- If applicable, define the routing, which is the sequence of operations required to manufacture the product.

- Assign each operation to the appropriate work center.

- Once all the details are entered, save the BoM.

- You can now use this BoM for manufacturing orders, production planning, and costing.

Conclusion

The Bill of Materials is a vital part of the manufacturing process, serving as the foundation for efficient production planning, inventory management, and cost control. Odoo’s BoM module offers a comprehensive solution that is both flexible and powerful, catering to the needs of various industries and manufacturing types. By leveraging Odoo’s BoM features, businesses can streamline their operations, reduce waste, and improve profitability.